Top precision machining Secrets

Through the years CNC equipment have become so commonplace that Generally they became a commodity device. It is not unusual to search out CNC equipment in retailers all throughout the world.

Precision machined items are about in day-to-day objects for instance car or truck engines, electric powered motors and even clocks. Nations for example Switzerland and Germany Have got a standing for there significant requirements of precision engineering and nowadays nonetheless do a very good work of it. Other nations also have a lesser of this popularity which include Japan and Great Britian.

Gang milling refers back to the usage of two or even more milling cutters mounted on a similar arbor (that is definitely, ganged) inside of a horizontal-milling set up. Most of the cutters might perform a similar variety of operation, or Every single cutter may well complete another kind of operation.

Facts About precision machining Revealed

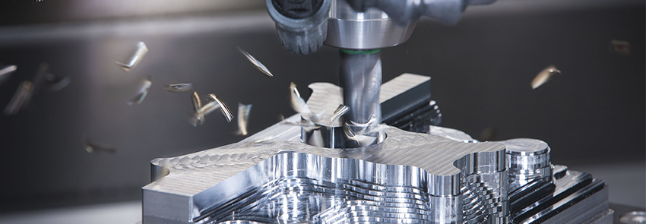

Milling operations are functions in which the cutting Instrument rotates to convey cutting edges to bear towards the workpiece. Milling devices will be the principal equipment tool used in milling.

We nonetheless retain our primary buyers, which speaks volumes about our devotion to good quality and customer support. You can learn more about our capabilities and providers when you pay a visit to us on line now!

BP Precision Machining provides a complete selection of tension tests companies, each high and small, to satisfy all tension screening needs of our consumers. Our tension screening providers incorporate proof screening up to thirty,000 PSI.

Ahead of numerical Manage, horizontal milling devices advanced very first, as they evolved by Placing milling tables below lathe-like headstocks. Vertical mills appeared in subsequent a long time, and equipment in the shape of insert-on heads to change horizontal mills to vertical mills (and later vice versa) have been normally made use of.

Finishing cuts are made use of to accomplish the element and reach the final dimension, tolerances, and surface complete. In generation machining Work, a number of roughing cuts are usually done official source over the get the job done, accompanied by 1 or 2 ending cuts. Roughing functions are completed at large feeds and depths – feeds of 0.

5 Simple Techniques For machining

The chopping surfaces of the milling cutter are usually fabricated from a hard and temperature-resistant material, so they have on slowly.

To stop Measurement Chance our good quality lab maintains the tools required to verify the precision abilities from the gauges useful for each inspection system. Instruments Doing the job at peak performance enable improve productiveness, profitability and satisfy regulatory specifications.

Photochemical Machining Layout Suggestions About 40 decades of Photochemical Machining practical experience Elcon has actually been noted for its Sophisticated photochemical machining process considering that 1967. We can create even particularly difï¬cult prerequisites by tightly managing each aspect of the method.

Machining needs focus to many details for the workpiece to satisfy the specs set out within the engineering drawings or blueprints. Beside the obvious complications relevant to proper Proportions, There is certainly the issue of achieving the proper complete or floor smoothness on the workpiece.

machining for Dummies

already exists as an alternate of the issue. Would you like to make it the principal and merge this question into it?